What are the specifications of led strip? Which ones are commonly used?

With the progress of the society, the led strip is more and more widely used in our daily life.But do you know what are the specifications of led strip? which ones are commonly used? Come talk to FITLED !

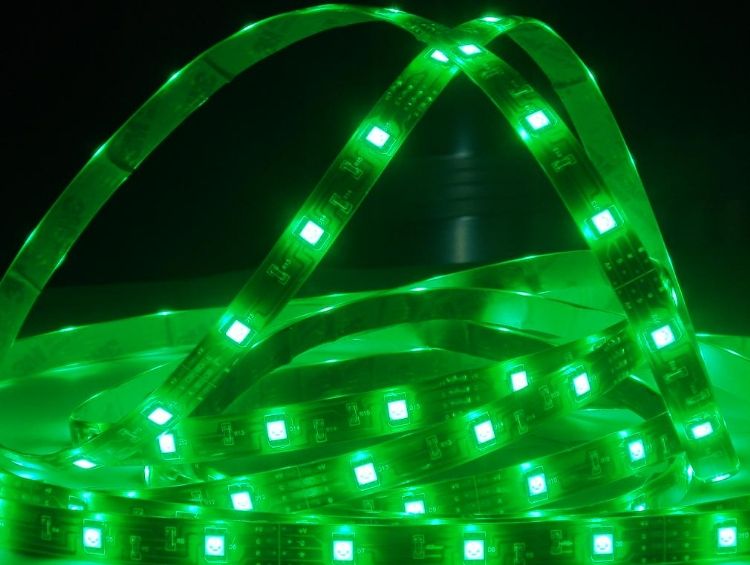

Led strip is both beautiful and practical, today we will learn about the knowledge of led strip, what is the led strip? Led strip refers to the led assembly in a ribbon FPC (flexible circuit board) or PCB hardboard, because its product shape like a belt named. Because use life is long (average and normal life is in 8~ 100 thousand hours), green environmental protection and be in all sorts of adornment industry gradually cut a figure. Light strip, is the abbreviation of LED light strip, most people are not used to the noun is too long, so the front of the LED to omit, called the light strip. In this way, the name of light strip also includes many old light strips that used to connect LED directly with wires instead of FPC or PCB, such as big two wire, big three wire, round two wire and so on. Of course, it also includes flexible light strip and hard light strip. LED light strips are generally divided into flexible LED light strips and hard LED light strips, but they generally include old LED light strips connected with wires, such as flat three-wire 4.3w/m, flat four-wire 6.48w/m, flat five-wire 8.64w/m, etc.

1. Flexible LED light strip USES FPC as assembly circuit board and patch LED for assembly, so that the thickness of the product is only the thickness of a coin and does not take up space; The general specifications include 18 leds 30cm long, 24 leds and 15 leds 50cm long, 24 leds and 30 leds. There are also 60cm, 80cm and so on, different users have different specifications. And can cut at will, also can lengthen at will and luminescence is not affected. The FPC material is soft and can be bent, folded and wound at will. It can be moved and stretched in three-dimensional space without breaking. Suit to be used at irregular place and the place with narrow space, also can be bent arbitrarily and coil because of its, suit to combine all sorts of design arbitrarily in advertisement adornment.

2. LED hardlight strip is assembled with PCB hardboard, LED is assembled with patch LED, and it is also assembled with direct plug LED. Different components are used according to different needs. The advantage of hard strip is easy to fix, processing and installation are more convenient; Weakness is cannot bend at will, do not suit irregular place. There are 18 LED, 24 LED, 30 LED, 36 LED, 40 LED and many other specifications for the hard light strip patch LED; There are 18, 24, 36, 48 and other different specifications with direct plug LED, there are front and side, side light also known as the Great Wall lamp.

Can be seen from the above introduction of the specifications of the led strip is not established, well, almost introduced these good, that is to share about the led strip, finally, interested friends can choose according to their own economic strength is suitable for their own good, believe that you will buy your satisfactory led strip! If you think to give the power of the thumbs up, FITLED will be more carefully to answer you, FITLED wish you a happy life.